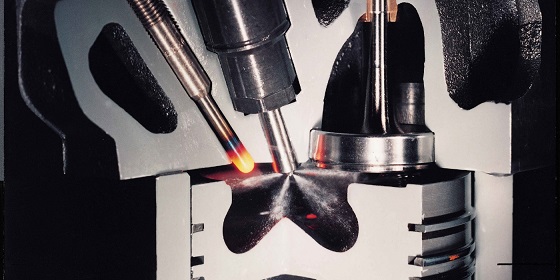

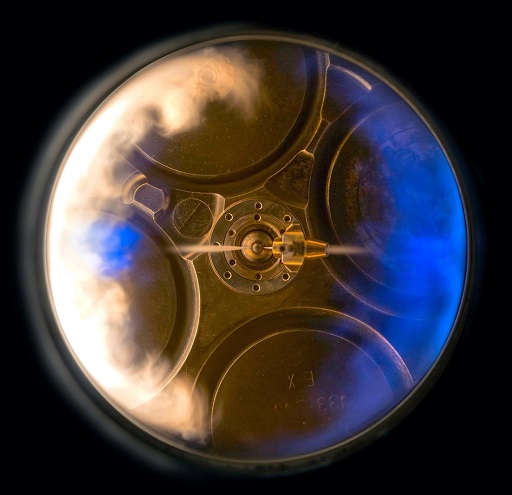

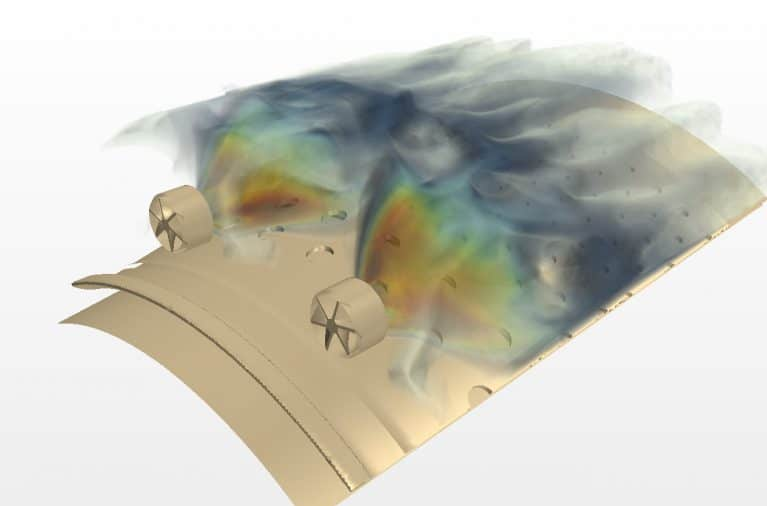

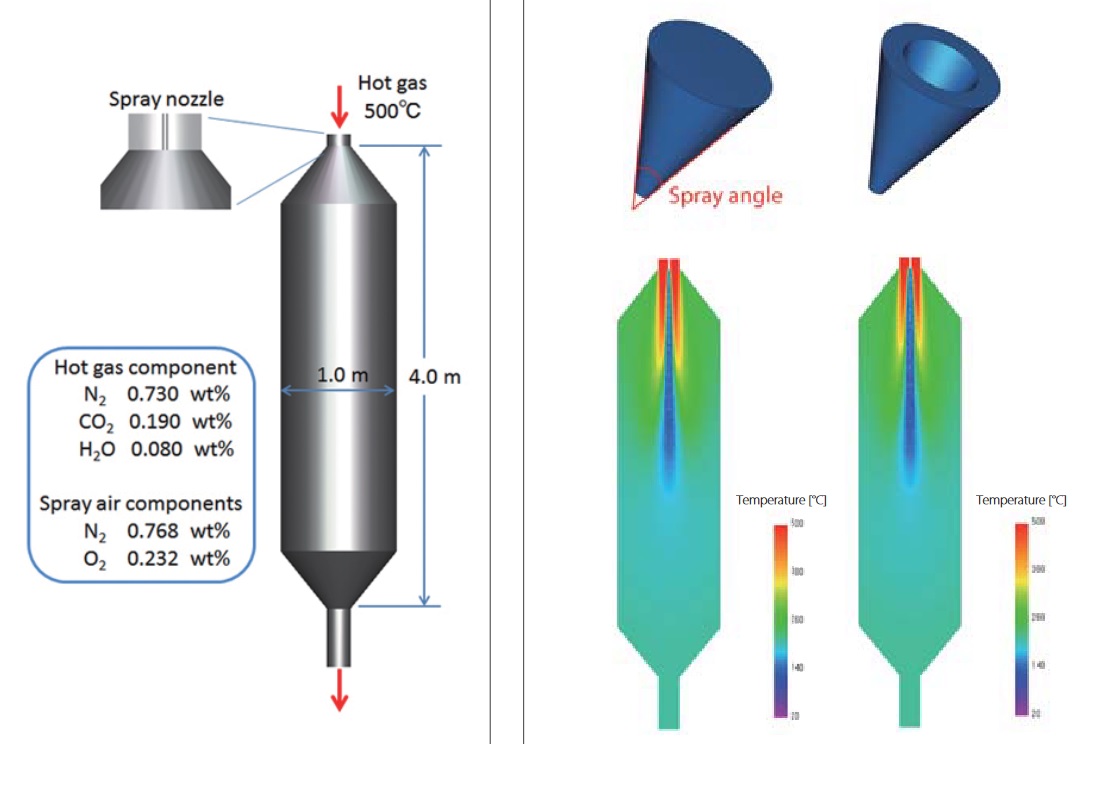

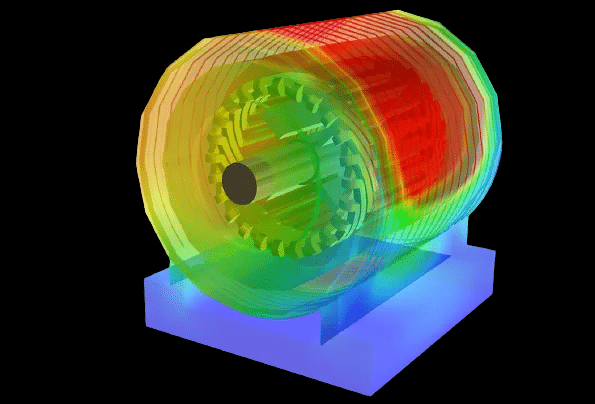

Fuel injectors and spray simulation are important aspects of the design and optimization of internal combustion engines. CFD software, such as AVL Fire, Siemens Star-ccm+, Ansys Fluent, and Converge, are well-equipped to simulate fuel injectors and spray processes, including liquid atomization, drop breakup, collision and coalescence, turbulent dispersion, spray cavitation, drop-wall interaction, and drop evaporation.

The simulation of fuel injectors and sprays can provide valuable insights into the behavior of internal combustion engines and can help to optimize their performance. For example, fuel injector and spray simulations can be used to evaluate the impact of different injector designs on fuel efficiency, emissions, and combustion stability. They can also be used to optimize the fuel injection strategy for different operating conditions, such as different engine speeds and loads.

In addition, fuel injector and spray simulations can help to optimize the combustion process by predicting the distribution of fuel and air within the combustion chamber, and by predicting the formation of pollutants and other combustion byproducts. This information can be used to optimize the design and operation of internal combustion engines for improved energy efficiency and reduced environmental impact.